Sew on a Button with a Thread Shank

33 Steps–That got your attention.

Actually, it may be that many, as have tried to include all the tips and tricks I’ve accumulated. And want this to be the be-all, end-all button sewing tutorial.

Sewing on a button isn’t difficult but it seems to be the ‘bugaboo’ of all sewing tasks. Have you ever babied a dangling button just to avoid having to sew it back on? Well, here’s the scoop on sewing on buttons that will always look good and last.

Just remember the following Secret and Tip:

A Thread Shank is the Number One Secret

That’s the extra thread between the button and the fabric that provides room for the correct seating of the buttonhole under the button. A thread shank is absolutely necessary for thick fabrics but is even advantageous for shirts and blouses. The shank also is a strong attachment as it is firmly wrapped with thread providing strength through more thread and more abrasion resistance. Abrading of the thread is the #1 cause of missing buttons; the buttonhole moves back and forth under the button as the garment is worn, buttoned and unbuttoned.

No. 1 Tip for Sewing on Buttons

Do not use knots–at beginning or end of stitching. Typical place for knots is on the wrong side; it’s just going to rub off during wear, and pretty soon the button is loose/lost.

Knots under the button get in the way of the shank, plus they too rub off due to abrasion from the buttonhole.

Tools

- 3″-4″scissors with sharp points; easy to get in tight spaces and nip threads

- Beeswax; this comes in a holder that separates threads for complete coating. Wax strengthens the thread, prevents knotting, eases needle threading. You can also use it to improve the glide on dresser drawers.

- Seam Gauge with Button Spacer

- Sharps Large Eye Hand Sewing Needles. Sharps are an all-purpose needle with a round eye for easy threading. The larger the size number the thinner the needle shaft. For thick or stiff fabrics, a size from 1-4 means a thicker shaft that won’t bend/break when pulled thru the fabric. An assortment of sizes in the 5-10 range will provide needles for most hand sewing needs.

- Thread–all-purpose polyester thread has high breakage and abrasion resistance–the button hole edges will rub on the thread. Use a double strand of thread so less stitches are needed to secure button; 3-5 stitches through the holes is sufficient, any more and it just looks messy.

- Fray Check/Seam Sealant secures thread ends and fabric fraying. It is washable and dry cleanable.

Button Sewing by Hand

Trim thread leaving short ends–a little extra thread can’t hurt just in case ends do want to work out.

Button Sewing by Machine

Only buttons with holes can be sewn by machine; buttons with integrated shanks must be sewn by hand.

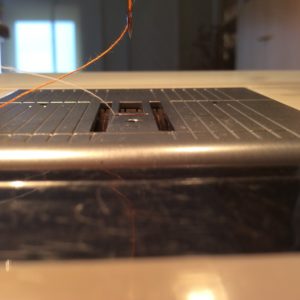

Bernina and other brands of sewing machines have specific presser feet for sewing on buttons. It even has a pin to sew over thus making a thread shank. I don’t have one so make do with the #20 Bernina open toe presser foot.

Lower Feed Dog. The Feed Dog is what grips the bottom of the fabric and moves it under the needle. Lowering the Dogs, keeps the fabric stationary so zigzag stitches can go back and forth between the button holes

Set zigzag stitche width to zero–see stitch width indicator upper right above. Stitch 2-3 times in one button hole to anchor threads.

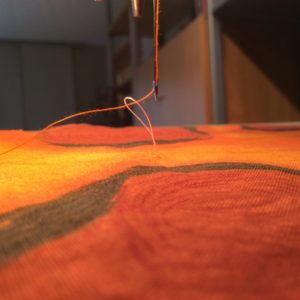

Set stitch width to 3-4–wide enough for needle to zigzag across both holes. Zigzag 3-4 times. Anchor as for first button hole.

Cut thread leaving a long tail–12-15″. Tug upper thread (orange) to pull up bobbin thread loop(white). Both threads should be under button.

Sewing on a Button that has an Integrated Shank

Buttons with integrated shanks are more common on large buttons suitable for coats. They still need a thread shank which provides strength and abrasion resistance. The tightly wrapped shank is stronger than just several thread loops through the button shank.

Anchor thread; fold fabric at button placement; stitch thru fold and button shank. Insert toothpick spacer under button shank and take 3-4 more stitches. A needle-nose pliers is a help in grasping needle in tight spaces

Remove toothpick spacer; wrap thread around thread shank and secure as for Hand Sewn/Machine Sewn Button.

And, this is absolutely Everything you need to know to successfully sew on buttons that will stay sewn!

Related

Not Just Any Seam Gauge

Pingback: plaquenil itching

Pingback: paxil and abilify

Pingback: metformin and fatigue

Pingback: buy neurontin

Pingback: order cialis india

Pingback: top rated essay writing websites

Pingback: discount propecia online

Pingback: college essay writer

Pingback: help with writing thesis

Pingback: writing a thesis paragraph

Pingback: synthroid 75

Pingback: diflucan sulfa allergy

Pingback: priligy usa

Pingback: missed clomid dose

Pingback: prednisolone hydrocortisone

Pingback: order doxycycline online

Pingback: albuterol 180 mcg

Pingback: ivermectin 3mg for lice

Pingback: azithromycin for sale

Pingback: lasix price in india

Pingback: how to order amoxicillin online

Pingback: cialis original for sale

Pingback: canadian pharmacy cialis 20mg

Pingback: cialis original for sale

Pingback: essay on issue business ethics theories

Pingback: help me with my english essay

Pingback: monthly cost of cialis without insurance

Pingback: write my essay online cheap

Pingback: how to write a research introduction

Pingback: what is the best custom essay writing service

Pingback: buy cheap cialis uk

Pingback: viagra comprar contrareembolso

Pingback: buy cialis 36 hour

Pingback: cialis original for sale

Pingback: buy viagra

Pingback: 5 mg cialis

Pingback: can i buy cialis online

Pingback: what is the dose of zithromax for strep throat

Pingback: viagra wat is dat

Pingback: buy cialis online viagra

Pingback: where to buy viagra in perth

Pingback: njwkqmbg

Pingback: cialis sale 20mg

Pingback: buy cialis drug

Pingback: can i buy cialis in toronto

Pingback: professional cialis

Pingback: how to buy cialis online uk

Pingback: cialis male enhancement

Pingback: generic cialis daily pricing

Pingback: buy cialis online viagra

Pingback: buy cialis without doctor prescription

Pingback: cialis shop in australia

Pingback: generic cialis canada

Pingback: viagra

Pingback: Oxytrol

Pingback: aarp recommended canadian pharmacies

Pingback: Alesse

Pingback: medical pharmacy

Pingback: pharmacy drug store

Pingback: order viagra online

Pingback: viagra over the counter walmart

Pingback: how to order cialis

Pingback: generic cialis online

Pingback: master thesis writing service

Pingback: what should i write my paper about

Pingback: research methodology thesis

Pingback: sildenafil generic viagra

Pingback: help write a research paper

Pingback: medical school essay writing service

Pingback: best dissertations

Pingback: helping others essays

Pingback: fast custom essay

Pingback: cialis mail

Pingback: cialis online

Pingback: custom essay writing services

Pingback: buy levitra online in usa

Pingback: prices of cialis

Pingback: Real viagra